how do mechanical trailer brakes work

The controller is connected to the vehicle battery and the stop light switch. When pulling the trailer or caravan forward the force is opposite to the arrows shown.

10 X 2 1 4 Trailer Electric Brakeassembly With Parking Trailer Electric Backing Plate With Parking Is Electrophoretic Coated Utility Trailer Axle Brake

Click to see full answer.

. When the tow vehicle moves forward and releases the brakes the neck extends and releases the surge brakes. The brakes are released. Ad Super Selection of Trailer Brakes for Boat RV Utility Cargo Work Trailers.

The tow ball in white exerts all the mechanical force from the towing vehicle onto the draw bar. The brake shoes return to their original positions causing the cam to rotate back to its original position. The coupling moves in and out of an overriding cylinder and in turn constricts the steel cables.

However when you apply your brakes the trailer or caravan tries to continue at the same speed inertia and. Electronic brakes They are automatically applied by the brake controller and can be manually operated by a manual control which is installed within reach of the driver. When the brake is applied the air then passes through the triple-valve system and air lines to the brake cylinder.

In order to release the brakes the triple-valve system fills a supply tank and uses air pressure. It is a legal requirement that all trailers over 750kg GTM have operating brakes. Mechanical brakes function via force delivered to a body in rotary or linear motion such as an axle shaft or wheel to slow or stop motion.

It is important that water and oil are not allowed to. Electric over hydraulic set up where an electronic control module applies power to a hydraulic brake actuator. With mechanical brake systems this means the cable between the over ride brake and the brake levers is required to increase in length accordingly the axle is moving away from the over ride coupling.

As the car slows down the trailer brakes are operated by a piston in the drawbar. It is made to slide on a ledge into the back half of the neck. Electric trailer brakes require a brake controller.

Considering this how do air brakes work on a semi trailer. So how do air brakes work on a tractor trailer. The neck of the trailer is two pieces.

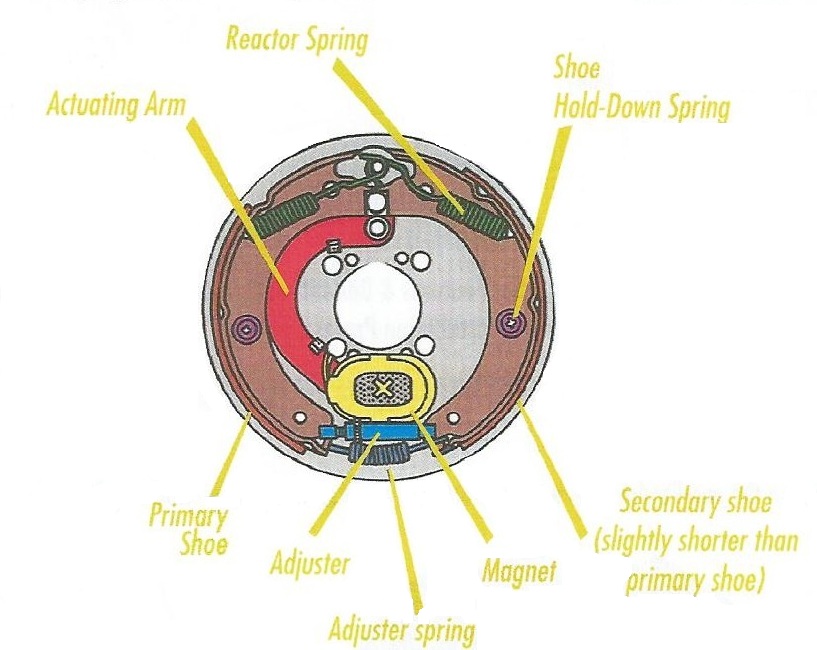

When the driver steps on the brakes it sends a current to the brake control in the vehicle. Mechanical These brakes mechanically move the actuator arm via steel cables which apply force to generate movement in the arm. In the drawing below shows the major components of an AL-KO over-run braking system.

Air is pressurized by an engine-mounted compressor. Latch open Left The coupling latch should be open at all times when driving forward to allow the brakes to work. See the mechanical brake and clutch assemblies page for more specific data on these devices.

Electric over hydraulic systems also have an in-car controller. This air is then held in the air reservoir. The pressure in the service line tells how much pressure the relay valves should send to the trailer brakes.

The electrics you require are. Mechanical brakes all act by generating frictional forces as two surfaces rub against each other. Below are some tips to ensure the brakes are working correctly.

Over-ride brakes which is the system where the tow coupling slides inside the hitch to operate either a mechanical or hydraulic system to apply the brakes. The slack adjuster returns to its original position. Because the cable cannot actually extend what occurs is the cable starts to activate the trailer brakes instead.

Mechanical override brakes use the tow coupling to manually pull a cable connected to the trailers brake drums. The brake shoe return springs force the shoes to release contact from the drum. Mechanical brakes are often in an assembly with a mechanical clutch for engaging and disengaging shafts.

For disc brake operation the process is slightly different. Hereof how do brakes work on a boat trailer. A brake controller is an electronic device that activates and as the word suggests controls the electric brakes of a trailer.

A brake controller can be roughly split in an interface positioned in the cab within the drivers reach and a main part responsible for activating the brakes of the trailer. An overriding coupling actuates the brakes. How Surge Brakes Work.

The compressor is a device situated on the engine that takes in and compresses air to be used in the pneumatic system. This in turn causes the braking shoes to contact the drum. How Disc Brakes Work.

Compressing the front piston pulls a rod acctivating the drum brakes on each wheel. The rod can be modified for the brakes to come sooner or later whatever makes you feel more comfortable. The stopping power or capacity of a brake depends largely on the surface area of frictional.

As the car brakes the coupling applies the trailer brakes. A master cylinder for the brakes is mounted to the back half of the neck and has a rod extending from the master cylinder to the front half of the neck. The front section with the hitch attachment is a separate piece.

These are permitted when the GTM is under 2000kg. When you step on the brake in your tow vehicle and slow down the trailer pushes against the hitch and presses a hydraulic cylinder. There are electrical wires running from the trailer connector back to each brake on the axle as well as to the trailer lights to create a complete circuit.

When the front neck is then pushed into the back that rod pushes into the master cylinder and then the brakes are applied. Electric trailer brakes use a brake controller which is situated in the tow vehicle. The brake control then sends a current back to the trailer to activate the brakes.

The more you slow down the vehicle the more pressure on the trailer brakes. This device modulates the electric current sent to the electric trailer brake when you press the brake pedal in your car. The pressure in the service line is controlled by the brake pedal and the trailer hand brake.

When they are adjusted properly surge brakes are smooth and easy to work with. How A Tractor Trailer Brake System Functions.

How Trailer Brakes Work How To Inspect Quick Short Tutorial Video Youtube

Trailer Brakes Options For Hunting Trailers Towing Quads And Buggies

Trailer Brakes Electric Vs Mechanical Trailer Brakes A2b Trailers

S L10000 Trailer Brakedrumr Boattrailer Brakedrum Brakecaliper Brakeassembly Caliper Axles Brakes Brake Https Boat Trailer Brake Calipers Calipers

Pneumatic Brake System Automotive Repair Truck Repair Willys Jeep

How Disc Brakes Work Automotive Mechanic Mechanical Engineering Car Maintenance

Torklift Central Surge Vs Electric Trailer Brakes Torklift Central Blogs

9 Trailer Hydraulic Brake Assembly Box Trailer Boat Trailers Camper Trailers

10 X 2 1 4 Trailer Brake Drum 6 On 5 5 Studs Drums Trailer Brake

12 X 2 Hydraulic Dacromet Free Backing Brakeassembly Capacity For 5 200 Lbs Axle Https Www Trailercaptain Com Hyd Trailer Axles Hydraulic Brake Calipers

Hydraulic Trailer Brake Assembly Demco Products

9 X 1 3 4 Trailer Hydraulic Brakeassembly We Offer Top Quality And Wide Ranges Of Brake Assembly Welcome To Contac Hydraulic Brake Calipers Brake System

Why You Should Upgrade Your Trailer To Surge Brakes To Electric Brakes

Trailer Brakes Options For Hunting Trailers Towing Quads And Buggies

Hydraulic Disc Or Hydraulic Drum Brakes For Your Trailer How To Choose The Right Brakes For Your Trailer Champion Trailers

10 X 2 1 4 Trailer Self Adjusting Electric Brakeassembly Capacity For 3 500 Axle E Mail Info Trailercaptain Com Https Utility Trailer Axle Trailer Axles

Trailer Brakes Electric Vs Mechanical Trailer Brakes A2b Trailers

Hydraulic Brake System When The Brake Pedal Is Pressed A Pushrod Exerts Force On The Piston In Th Automotive Mechanic Car Brake System Automobile Engineering